3D PRINTING ECHNOLOGY (ADDITIVE MANUFACTURING)

|

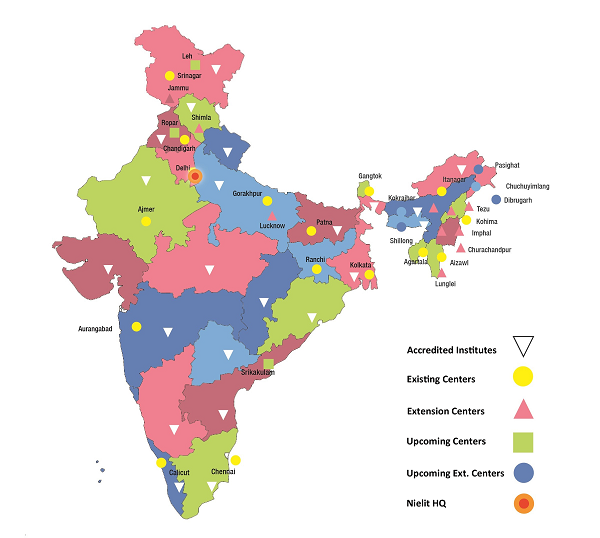

Objective: To create a re-skilling/ Up-skilling ecosystem in emerging and futuristic technologies to facilitate continuous skill as well as knowledge enhancement of the IT professionals in line with their aspirations and aptitude in a self-paced digital skill environment.“ 4.2 lakh IT Professionals over a period of 3 years. Resource Centres: C-DAC and NIELIT through Hub-n-Spoke mode Target Beneficiaries • IT employees in IT firms and non-IT firms • Non-IT employees who use new and emerging technologies • Re-skill/Up-skill employees whose IT skill is obsolete • Central Govt. & State Govt. employees • PSUs and Autonomous (Govt. Employees) • Fresh Recruits – Internship/apprenticeship. Stakeholders: MeitY, NASSCOM, PMU, C-DAC, NIELIT and other Stakeholders NASSCOM

|

|

|

|

3D Printing/Additive Manufacturing Lab Objectives: 3D Printing is a manufacturing technology that is much faster than all conventional manufacturing technologies. Many manufacturers use 3D printing or additive manufacturing technologies to produce airplane parts, prosthetic limbs, and even 3D-printed medications. 3D printing also provides many opportunities to aid visual and practical learning across the sciences. 3D-printed components are often used as test models for scientific experiments across different disciplines, including mechanical engineering, aerospace, and robotics. Additive Manufacturing / 3D Printing Lab is equipped with various configurations of 3d Printers, Professional 3D Scanner, also has flagship CAD/CAM software packages and high-end CAD/CAM workstations to meet the present industrial requirements. The lab is aimed at giving exposure and enhancing the knowledge and skills of engineers involved in the operation use of 3D Scanners, 3D Printers, CAD packages and for those who want to provide training to others in this area. It gives exposure and on hand experience in the field of Additive Manufacturing / 3D Printing, 3D scanning and, reverse engineering, some of the facilities available as follows: |

Under Futures Skills Prime Project on "3D Printing Additive Manufacturing Technology" at NIELIT Aurangabad centre has setup latest 3D Printing facilities and announced following up skilling course as per the outlines are prepared and syllabus got vetted by NIELIT academic committee with representatives from industry and academia.

. Introduction to 3D printing and CAD Modelling 2. Additive Manufacturing Technologies 3. Reverse Engineering and Rapid Prototyping 4. 3D Printer installation, Operation and Trouble shooting 5. Awareness course on Additive Manufacturing 6. Introductory course on Additive Manufacturing |

|

|

NIELIT Setup for FDM Technology : Ultimaker Ender DIY 1-touch 3D printer kit has easy assembly mechanism with a thermal runaway protection function for education and architecture module making. It has a build volume of 220 x 220 x 250mm, a Build Tak-like heated build plate, power recovery mode and a tight filament pathway that makes it easier to print with flexible materials. The Creality Ender 3 is an excellent option for beginners or makers on a budget. Ender 3D Printer PLA/ABS Materials

|

NIELIT-A: Additive Manufacturing & Prototype Product Design Laboratory MOJO 3D Printer The Mojo 3D Printer from Stratasys brings affordable, professional 3D printing to your design process. Powered by proven Fused Deposition Modeling (FDM) technology, you can trust the Mojo to empower your design creativity. Whether you’re testing for form, fit or function, Mojo works easily with your CAD software- bringing your ideas to life with just the push of a button. FDM technology allows you to build spot- on functional concept models and rapid prototypes. The Mojo 3D Printer allows you to print professional grade 3D models in ABSplus thermoplastic – at a price lower than other professional 3D printers. |

|

|

1) At NIELIT Aurangabad centre 3D Printing laboratory has equipped with latest equipments and Design software's & Hardware's to support AM & 3D Printing technologies as mentioned below:

2. Artec Space Spider-Industrial 3D scanner Artec Space Spider is a high-resolution 3D scanner based on blue light technology. It is perfect for capturing small objects or intricate details of large industrial objects in high resolution, with steadfast accuracy and brilliant color. The scanner’s ability to render complex geometry, sharp edges and thin ribs sets our technology apart. It is an ideal industrial 3D scanner for high resolution capturing of objects such as molding parts, PCBs, keys, coins or even a human ear, followed by the export of the final 3D model to CAD software. Space Spider offers almost unlimited possibilities in areas such as reverse engineering, quality control, product design and manufacturing. 3. Catia V5 CATIA software (an acronym of computer-aided three-dimensional interactive application) is a multi- platform software suite for computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), PLM and 3D, developed by the French company Dassault Systèmes. CATIA is increasingly chosen as the primary 3D design system for many companies, the worldwide demand for CATIA designers is difficult to meet. When you learn to use CATIA you also learn to work with leading-edge technology and play an important role in innovation. You get to put your imagination to work at full-speed because with CATIA there are no boundaries. Using CATIA, you are equipped with the most versatile design tool that’s applied in a multitude of industries. |

4. PTC Creo Creo is a family or suite of Computer-aided design (CAD) apps supporting product design for discrete manufacturers and is developed by Parametric Technology Corporation (PTC). The suite consists of apps, each delivering a distinct set of capabilities for a user role within product development. Creo provides students the opportunity to work with state- of-the-art 3D CAD software, enabling them to take ideas and concepts and turn them into products. Creo offers the best preparation to become an Engineer of the Future, by putting design, analysis, and simulation tools directly in the hands of students. 5. AutoCAD: AutoCAD is a commercial computer-aided design (CAD) and drafting software application developed and marketed by Autodesk. With AutoCAD, you get access to seamless workflows, specialized industry toolsets, and new automations to help you achieve the ultimate productivity in 2D and 3D design. Get powerhouse performance, visualize Xref changes, enhanced Blocks capabilities, and version control to take your designs to the next level.

Target audience for the courses on 3D Printing Additive Manufacturing"

For detail Contact: Sh.B.B.Sorte, Co.Invertisigator balasaheb@nielit.gov.in Co-Lead Centre, NIELIT Aurangabad |