Govt. Officials Programme - 3D Printing/Additive Manufacturing

About: A Re-skilling / Up-skilling programme in ten emerging technologies for Senior Govt. officials in policy- and decision- making roles like Govt. secretaries, officers, senior engineers, architects, scientists, etc. under Future Skills PRIME project by MeitY, Govt. of India in collaboration with NASSCOM.

Objective: 3D Printing is an emerging technology showing potential to reach new markets and create new jobs. Students who complete this programme should be able to:

- Demonstrate the viability of utilizing Additive Manufacturing technology to develop product prototypes

- Develop skills to allow for prototype models for a range of products to be produced

Why 3DPAM: 3D printing becomes more and more common, it'll become easier and easier for inventors and creatives to turn their ideas into realities. 3D printing already makes it far easier for inventors to produce prototypes. In the future, the manufacturing process could be carried out by 3D printing as well. 3D Printing is an emerging technology showing potential to reach new markets and create new jobs. Students who complete this programme should be able to:

- Demonstrate the viability of utilizing 3D printing technology to develop product prototypes

- Develop skills to allow for prototype models for a range of products to be produced

- Develop skills for CAD modeling

The broad implementation model of GoT entails that the programs are carried out in collaboration with government organizations. The beneficiary government institute would identify in a list the technical manpower to be trained in corresponding future technologies based on envisioned training objectives and the anticipated future plan of the organization. Based on the needs as elaborated by beneficiary government institute, Resource Centre (Lead/ Co-Lead) may customize the future skilling programme to suite the target beneficiaries in the respective organization.

Fees, Mode and Duration: The duration of the program is 40 hrs. (Approx. 2 weeks). The training programme will be conducted in 100% online mode and has been scheduled from 11th May 2022. The programme fee is funded under the Future Skills PRIME Project, sponsored by MeitY, Govt. of India. There is an option for Offline hands on session between 20th May and 24th May 2022.

Program Details:

|

Name |

Industrial training in Additive Manufacturing & its Applications |

|

Duration |

2 weeks, Five days a week, 4 hours duration daily Pre recorded sessions of Theory and Practical will be available in our LMS. Participants will use our LMS to learn this Online Course. Two Live Sessions will be provided for Queries

|

|

Total Hours |

40 Hrs (Theory: 20 Hrs + Tutorials/demo/virtual practice sessions: 20Hrs)

|

|

Objectives |

3D Printing is an emerging technology showing potential to reach new markets and create new jobs. Students who complete this programme should be able to:

1. Demonstrate the viability of utilizing Additive Manufacturing technology to develop product prototypes

2. Develop skills to allow for prototype models for a range of products to be produced |

|

Expected Outcome |

After the course, the learner will be able to

|

|

Pre-requisite |

The program is targeted at middle/junior level government officials who are keen to undergo a significant change in their career path |

Detailed Contents

|

Module |

Topic |

|

Module1 |

• Introduction to Additive Manufacturing: Introduction to AM, AM evolution, Distinction between AM & CNC machining, Advantages of AM • AM process chain: Conceptualization, CAD, conversion to STL, Transfer to AM, STL file manipulation, Machine setup, build , removal and clean up, post processing. • Classification of AM processes (ASTM): Material Extrusion, VAT Photo Polymerization, Sheet Lamination, Powder Bed Fusion, Binder Jetting, Material Jetting and Direct Energy Deposition |

|

Module 2 |

• Prototyping using 3D Printer File conversion for slicing, Optimization for orientation, Print settings & building |

|

Module 3 |

• Design for AM: Design guidelines for Polymer based material extrusion, Polymer based laser powder bed fusion, Polymer based VAT Photo polymerization. Design guidelines for Metal based laser powder bed fusion & Electron beam melting and Metal based binder jetting. |

|

Module 4 |

Medical models, Rapid tooling, Bi-metallic parts, Remanufacturing, Aerospace, defense, automobile, and general engineering industries

Support material removal, surface texture improvement, accuracy improvement, aesthetic improvement, property enhancements using non-thermal and thermal techniques. |

What you achieve:

- Explain how technology shifts throughout history have made 3D printing possible

- 3D printing allows students to create prototypes of items without the use of expensive tooling required in subtractive methods.

- Exploring software for slicing and path generation.

- Experiment with alternative solutions and software

- Apply professional, ethical, legal, security and social issues in the design of AM processes.

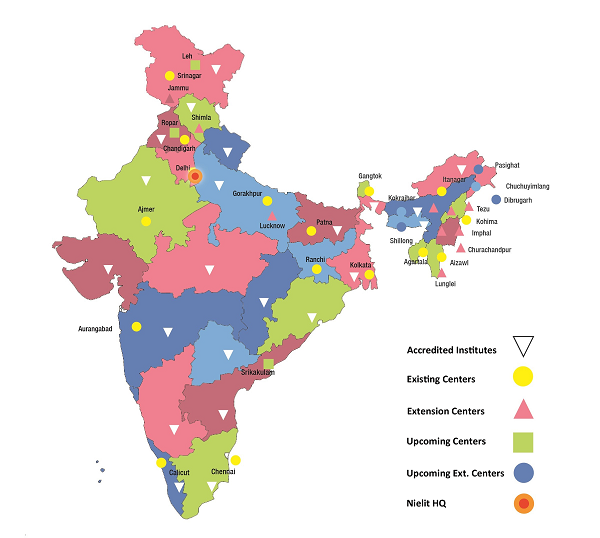

Assessment and Certification: NIELIT, Calicut (an autonomous body under Ministry of Electronics & IT (MeitY), Govt. of India.) being identified as the Lead Resource Centre for 3D Printing/Additive Manufacturing will offer course in above said programme and will be the authority to assess and certify the successful candidates who would have undergone the training programme.

Epilogue: So, come forward and join us with a rewarding journey by nominating officials from your organization as per above mentioned details of the programme and take this opportunity to strengthen your internal technical manpower in futuristic emerging technologies.