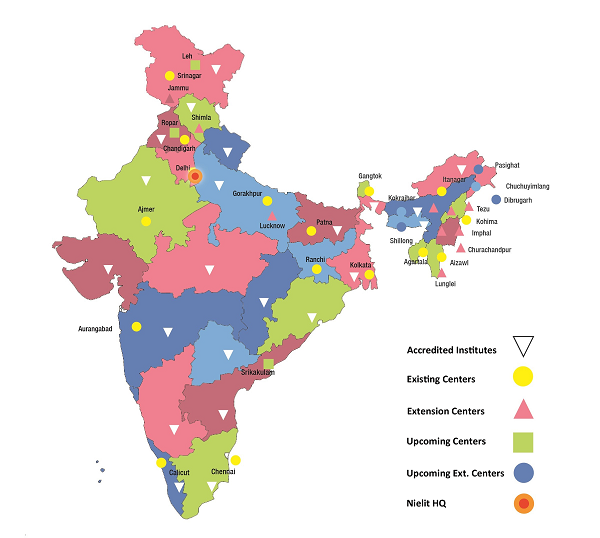

Industrial Automation

| Objectives: | |

|

Recent trend of merging control systems associated with both factory and process automation demands knowledge from diverse fields. The purpose of the lab work is to study automation of time critical systems that demand precise real-time readings and control. |

|

| Main Equipment's Available | |

|

1. NI 9217 4-Ch PT 100 RTD 24-bit, 100S/s/ch The NI‑9217 is compatible with 3‑ and 4‑wire RTD measurements, and it automatically detects the type of RTD (3‑ or 4‑wire) connected to the channel and configures each channel for the appropriate mode

|

|

|

2. NI PCIe-6321, X series multifunction DAQ (16 AI, 24 DIO, and 2 AO), 250kS/s single channel sampling rate: The PCIe‑6321 offers analog I/O, digital I/O, and four 32‑bit counters/timers for PWM, encoder, frequency, event counting, and more.

|

|

3. NI USB-6211 Bus-powered M series Multifunction DAQ device It offers analog I/O, digital input, digital output, and two 32 bit counters. The device provides an onboard amplifier designed for fast settling times at high scanning rates. |

|

|

4. NI USB-9211A, 4 Ch., 24-Bit Thermocouple input module: Plug-and-play connectivity via USB. Compatibility with J, K, R, S, T, N, E, and B thermocouple types |

|

5. Compact RIO CompactRIO (or cRIO) is a real-time embedded industrial controller made by National Instruments for industrial control systems. The CompactRIO is a combination of a real-time controller, reconfigurable IO Modules (RIO), FPGA module and an Ethernet expansion chassis. |

|

|

6. Programmable Logic Controller PLC is used for control applications as in special purpose machines for milling, drilling, packaging etc. PLC senses inputs from field (using its input cards), for example from a level sensor, a proximity switch, pushbutton etc. PLC’s have been programmed in a language called as ladder language.Siemens S7 300 & 1200 PLC, SCADA, HMI is used for PLC programming on Siemens PLC software Simatic Manager & TIA portal V13 with Digital I/O as well as Analog I/O. SCADA designing with WinCC basic & advance Siemens SCADA software, HMI TP700 comfort programming & its applications. |

|

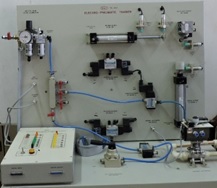

7. Electro-Pneumatic Trainer Kit Electro-pneumatic control consists of electrical control systems and operating pneumatic power systems. In this solenoid valves are used as interface between the electrical and pneumatic systems. Devices like limit switches and proximity sensors are used as feedback elements.

|

|

|

8. Level Measurement Capacitive Level Sensors also referred as Radio Frequency (RF) level sensors, are used for measuring process level at a specific point, multiple points or continuously over the entire vessel height. Level change results in a variation of capacitance value around the probe, depending upon the degree of immersion |

|

9.Electro Hydraulic Trainer Kit Electro Hydraulic Trainer outlines the basic Principle of Hydraulic Control System, Hydraulic Control System Components & its applications using electronic proximity position sensor &electro-mechanical actuators (solenoid valves). |

|

| Some of the practical project experiment: | |

|

1. Optimized Operation of Induction Generator for Small-scale Wind Power.

2. High Precision Stepper Motor Controller Implementation on FPGA with GUI on LabVIEW.

3. Real Time Data Monitoring of PV Solar Cell Using LabVIEW and DAQ.

4. Forest Fire Detection Using Optimized Solar-Power Zigbee Network

5. Optical Character Recognition Based Speech Synthesis System Using LabVIEW

6. LabVIEW and Web-Server Based Human Body Monitoring System

|

|