Automation technology

| Introduction: Purpose of this course is to provide a basic level exposure to automation technology. Student will be exposed to cutting edge technologies in automation, knowledge new developments in automation. Student will be industry ready for Automation technology hydraulic pneumatic and electric automation. Stiff competition, higher quality standards and growing concerns of safety & environmental damage have pushed the Industrial sector to adapt state-of-the-art Automation Techniques for effective utilization of resources and optimized performance of the process plants. Recent trend of merging control systems associated with both factory and process automation demands knowledge from diverse fields. Automation applications span plant automation, discrete and batch process control, embedded machine control and manufacturing production line automation. | |

|

|

|

1.History:Automation, in the sense of using machines or equipment, dates back to the 11th century when miners used waterwheels to drain out water from underground tunnels and shafts. The modern form of automation took shape during the Industrial Revolution in the 1800s when automated processes and tools were used to increase factory productivity. |

2.Significance of Automation Technology:McKinsey Global Institute estimated that as many as 375 million workersor 14 percent of the global workforce would have to switch occupations or acquire new skills by 2030 because of automation. Contrary to popular belief that automation will replace manufacturing jobs in India, the manufacturing sector is expected to touch US$ 3.5 billion in 2020 creating 130 million jobs. Automating low-end jobs with repetitive tasks like Bajaj Auto adopting cobots back in the day in their Chakan plant to perform tasks like material handling and bolt tightening. NITI Aayog and ABB India signed a Statement of Intent (SoI) to support the Indian government realize its ambitious vision of ‘Make in India’ through advanced manufacturing technologies. Jointly, NITI Aayog and ABB are working with government ministries to discuss solutions using industrial automation, and digitalization |

|

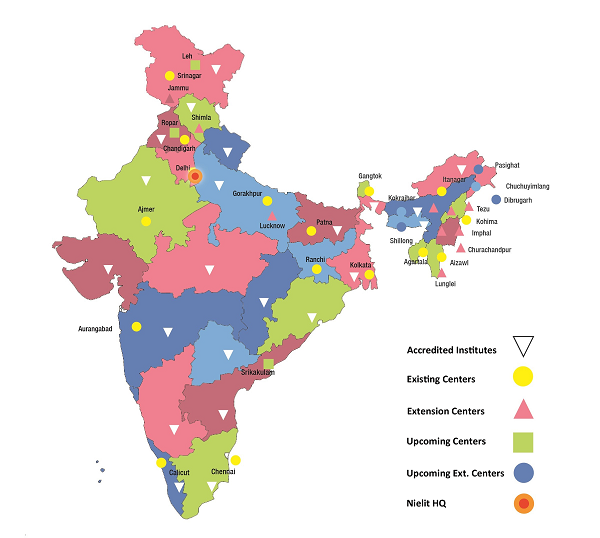

3. Potential use cases of the Automation Technology:

|

|

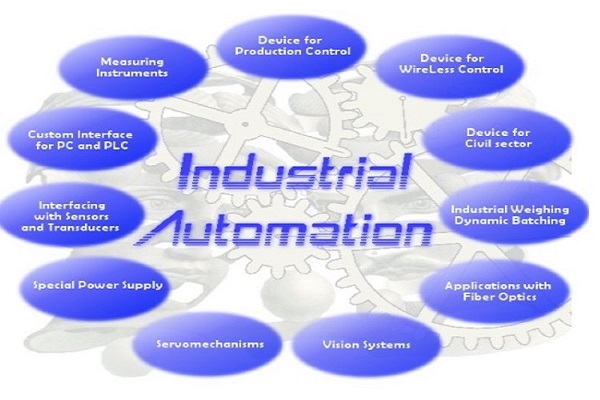

| 4. Programmable Logic Controller :PLC is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program to control the state of output devices. They are industrial computers used to control different electro-mechanical processes for use in manufacturing, plants, or other automation environments. Another advantage of a PLC system is that it is modular. That is, you can mix and match the types of Input and Output devices to best suit your application. Ladder logic is widely used to program PLCs, where sequential control of a process or manufacturing operation is required. Ladder logic is useful for simple but critical control systems or for reworking old hardwired relay circuits. As programmable logic controllers became more sophisticated it has also been used in very complex automation systems |

5. Why Industrial Automation is Important? The industrial world is facing many technological changes which increased the urgent demand for the premium quality products and services that can only be supplied by a high level of productivity. Globalization – Global industrial automation market demands superior, practical services Productivity – Automation companies want to enhance their productivity by producing a higher level of Automation. The key factors include costs, time and quality The major advantages of using automation are: Reduced direct human labor costs and expenses , Increased productivity,Enhanced consistency of processes and Delivery of quality products |

|

6.Some Industrial Automation Companies: Siemens, ABB, Emerson Process Management, Rockwell automation, Schneider Electric, Honeywell process solutions, Mitsubishi electric, Yokogawa electric, Omron automation, Danaher Industrial Ltd |

7. Online Course Offered by NIELIT:

|

|

8.Reference: https://www.meity.gov.in/content/industrial-applications |

Registration and Contact Details Saurabh Bansod (9834081669) Surya Charan (8500744697)

|